About Gig & Trina

Gig Drewery, alongside his wife Trina, boasts an impressive legacy spanning over four decades in addressing onsite wastewater challenges. Their journey began in the early 1980s when they began installing aerobic treatment units (ATUs) in East Texas where they played a pivotal role in obtaining state approval for ATU usage. Gig is a licensed Texas installer II, licensed maintenance provider and a licensed site evaluator. They went on to found Hydro Action and transitioned from installing to designing and developing NSF-tested and certified ATU products.

Gig’s contributions extend beyond innovation; a number of his patents have become public domain and continue to shape the industry. As a founding board member of the National Onsite Wastewater Recycling Association (NOWRA) and the inaugural president of the Texas Onsite Wastewater Association (TOWA), Gig has left an indelible mark on the sector. Additionally, he has lent his expertise to the NSF joint committee for a number of years.

The couple’s enduring commitment to addressing onsite wastewater challenges has culminated in the development of the groundbreaking innovative RioVation® BioMaze® technology which converts septic tanks into Biofilm Reactors otherwise known as an ATU’s. Gig and Trina’s unwavering passion underscores their dedication to finding sustainable, cost-effective solutions for the industry and the environment.

About Stephen Moeller

Stephen Moeller’s career journey in the industrial sector began with a solid foundation in the electrical wholesale business. Building on this early experience, he transitioned into the field of industrial electrical, controls, and instrumentation contracting, gaining valuable expertise in these areas.

For over a decade, Stephen played a pivotal role in a global organization, where he focused on developing and managing business relationships and procurement for large-scale construction projects. His dedication and strategic approach contributed significantly to the success of these initiatives.

In collaboration with Gig Drewery, Stephen is involved in the development and marketing of the RioVation® BioMaze® product line, demonstrating his entrepreneurial spirit and ability to bring innovative solutions to market. Stephen’s interest in wastewater treatment led to extensive research into the field’s current state and historical evolution. More recently, he has delved into microbiology, recognizing its importance in advanced wastewater treatment. Stephen’s commitment to continuous learning and exploration is a testament to his drive to stay at the forefront of his fields of interest.

Soil is an Excellent Medium for Wastewater Treatment

BUT

Estimated that less than 1/2 of the soils making up the United States are suitable for Wastewater Treatment

AND

The Soils that are suitable for Wastewater Treatment live in very unpredictable and hostile environments

SO

We can keep rolling the dice and leaving more than 4 billion gallons a day of septic effluent treatment to chance in the soil

OR

We move the treatment into the tank where ~90% of the waste can be removed and leave the remaining ~10% for the soil to finish

The RioVation team is dedicated to designing and manufacturing practical and affordable solutions for onsite wastewater treatment challenges which impact people and our environment. We care about the contractors we work with and design treatment solutions for, their customers, and the environment that we all share and value.

Call us today:

(903) 215-8855

Our Products

True Aerobic® (ATU) Conversion Kit-Suspended Growth Model SG2872

True Aerobic® (ATU) Conversion Kit-Suspended Growth Model SG2872 converts an existing septic tank into an Aerobic Treatment Unit (ATU).

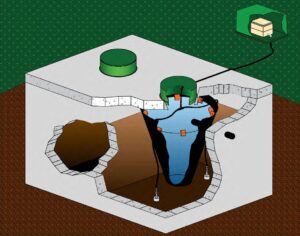

BioMaze® Kit Model BM2624 (300-750 GPD)

The RioVation® BioMaze® Conversion Kit product, converts an existing septic tank into a Biofilm Reactor. When the septic tank is converted, the effluent coming out of the septic tank and going into the drainfield becomes clear and odorless, high in dissolved oxygen and aerobic bacteria.

Level Control-Filtered Pump Vault

Install the Filtered Pump Vault into your septic tank through the single access opening and immediately control the level in your septic tank while forcing the effluent into the drainfield.